So I picked up some of Walthers' N scale modular bits and pieces that were being clearanced out at $2.99 a pack. These have been out for a while, so I'm sure more accomplished modelers than I have already commented on these kits, but having recently completed a structure using them, I feel the need to publish a couple of observations.

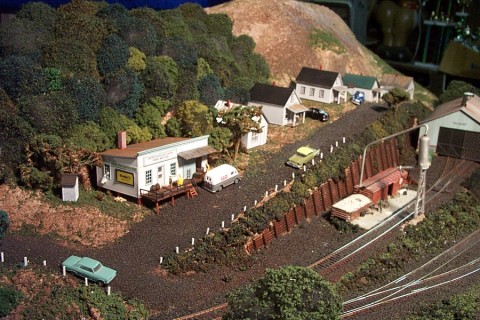

First, I should clarify that over the years that I've built a number of structures using Design Preservation Models' modular wall system, and despite the limited variety that's offered, I've had a lot of fun working with it. Here's a couple of modest examples:

|

| The commissary at the west end of Ridgeley Yard |

|

|

|

| The Westvaco Paper Warehouse at Luke |

|

|

|

| The Department of Public Works at Ridgeley |

|

|

|

|

| Hudson Motors Assembly Plant office, Delmarva Model Railroad Club |

...among others.

Generally, the parts need a little work to put them together, but they're certainly "vanilla" enough be adapted into a variety of situations.

I think the size of the panels, the brick pilasters used to join them, and the variety of window/door arrangements are at the very least adequate. The main feature I've come to appreciate, though, is the spacing of the loading dock doors. Run in a simple alternating pattern, you can line up 40' boxcars and align them to the loading doors without uncoupling the cars.

So let's take a look at the Walthers' Modular system.

Again, there's a reasonable variety of doors and windows, but I can't help but wonder if they didn't design these things to be used by HO modelers. The windows are modeled as double hung (top and bottom sashes that slide up and down in tracks along the side) but they're enormous. The doorway openings are excessively tall, and even with the transoms, the doors appear much taller than they need to be.

While it's not unusual for a brick industrial building to have larger windows, they're not typically going to be double hung windows. You'd be more likely to find large steel framed fixed windows, perhaps with a smaller section that's hinged so it can provide ventilation. This would be a more typical arrangement, shot in Columbia, Pa:

These are clearly double hung windows, but they measure approximately 3 feet wide by 6 feet tall, compared to the Walthers' windows, which tip the scales at a whopping four feet wide by 9 feet high. Now, back in the day, I worked in a huge loft industrial building in Baltimore, which sported large banks of 4' x 8' double hung windows, three windows across.

|

| The Candler Building in Baltimore |

... But there were a LOT of them...and the building was HUGE and constructed in poured concrete with a "curtain wall" exterior, in other words, the outside wall isn't a load bearing wall (other than bearing its own weight). The design used by Walthers', as well as by DPM, features individual windows with large expanses of brick and pilasters, which is more indicative of a load bearing wall, where the exterior wall is carrying the weight of the floor systems, roof system plus whatever's sitting on them. From an engineering standpoint, this type of architecture is limited in how high it can be built, so I always gasp when I see model building stacked to 15 or 20 stories, because it just doesn't look right.

The dimensions between the floors of the modular kit are also a bit suspect. While the first floor of a brick industrial structure will typically be 14 to 18' to accommodate trucks backing into the loading docks, and 20' to account for freight cars on an interior siding, the upper floors drop back to a lower height, perhaps 10 to 12 feet. Walther's maintains the same floor heights all the way up, making the building more massive than might be realistic. This is due to the interchangeability of the wall panels to serve as any floor's exterior. DPM solved this problem quite simply, but it plum evades Uncle Wally.

I don't like the way the wall segments are broken down. There are double wide sections offering dual windows on either side of a cast in brick pilaster, but no arrangements that are two stories tall. Therefore, when you combine sections to make a two story (or more) building, you're going to have a lot of horizontal seams that you have to deal with. (DPM provides 2-story upper walls, eliminating this problem, and the single story sections designed for your first floor feature some brick trim across the top to justify the break in the brick work.)

While the pilasters provided are cleverly designed to help lock the wall sections together, like the wall sections themselves, these parts only rise one story tall. This leaves the modeler with even more horizontal joints in the brickwork that are a little trickier to line up and disguise than they need to be. A trim set providing two story pilasters would allow for faster assembly, and also would strengthen the overall construction by spanning the joints in the walls.

I'm not crazy about the two cornices that are offered, either. The peaked one just doesn't look right to my eye, and ends up creating a building that screams out "I built this with the Walthers' Modular System" more than it says, "Yeah, that's a plausible big industry". I also don't like the angled brickwork that runs up the gables. I'm sure this condition exists somewhere in nature, but I feel like a stepped parapet, or some other "false front" treatment would be more generic when it comes to masking a pitched roof. The straight sections are nice, but there aren't enough of them in the kit if you're going for a large building, especially one that's not a background flat. Same goes for the single story pilasters. I used the system to build a flat behind my station, and came up two pilasters short. DPM gives you an abundance of joinery in their offering, which again adds flexibility in terms of how you "cut up" your facades.

|

| The unpainted structure behind the Cumberland Station is (obviously) whipped up from Walthers' Modulars. |

The big killer, though, is the loading doors. Since the architecture featured has the appearance of an early to mid 20th century building, you'd expect the doors to be logically spaced to receive 40' boxcars. No dice. If you put the loading doors, which are single wall sections, side by side, they're way too close together, and if you hop scotch them with brick blanks, they're too far apart. They're too far apart for 50 footers, too, so pretty much anything you roll up to the loading docks is going to have to be uncoupled and spotted at the doors. Not too big an inconvenience, I suppose, just one more thing on the stack of other small things that I regard as shortcomings of this system.

Now, just to prove that I can be a little bit fair minded, I'll say I really like the brick detail in the walls, the interlocking pilasters are a neat trick (although I'd like it better if they had some 2-story pilasters), and the system can work well for a large industrial complex, which Walthers has shown through the various industry kits they offer that utilize the system. I also like that the system is cast in a reasonably opaque material, since I like to install interior lighting. Although, all the joints and seams that result from the assembly design create a little more work when chasing down light leaks... It should also be noted that the roof detail kit offered in this line is outstanding, with a variety of vents, tanks and equipment that really enhances the typical "top down" view most of us have when operating our trains.

I guess the biggest beef I have with the Walthers' system is that for all its various parts, it lacks the flexibility that is offered by the less extensive line provided by DPM. With its giant windows, multiple small parts, odd door spacing and tall upper floors, you don't want to crowd too many of these together. The parts also don't lend themselves to other types of buildings, such as offices near the factory, or structures you might find in a downtown area. Also, lacking compatibility with other kits make the parts harder to kitbash into other configurations such as I've enjoyed doing with DPM parts.

I'm sure I can find other things to make with this system, but I'm afraid the attempt to make it too interchangeable makes it less flexible for multiple uses on a single layout. The proportions seem to lend themselves to larger industries, but using the tiny sections to create a massive building would be time consuming and potentially maddening, and without using some additional bracing, it would end up getting wavy due to all the joints in the walls.